How To Calculate Parenteral Product Viscosity Using The Rotational Rheometer Method

What is viscosity?

Viscosity is the amount of internal friction (or internal resistance) between components in a fluid. Honey is an everyday example of a highly viscous product. Products with high viscosity are considered “thick” and flow slowly. In contrast, water is an example of a fluid with low viscosity. Products with low viscosity are considered “thin” and flow quickly and easily. A fluid’s flow speed depends on how fast the molecules in a fluid can rearrange and move past each other. Thus, liquids with small molecules tend to have low viscosity. Liquids with long-chain molecules (such as hyaluronic acid) have higher viscosity. Also, liquids with molecules that can form bonds with each other are more viscous. The bonding of glucose and fructose in honey is why honey is so viscous.

What types of injectable products are viscous?

Viscous injectable formulations often have high concentrations of large molecules or non-aqueous solvents. Highly viscous formulations contain both. Examples of large molecules include monoclonal antibodies, proteoglycans, and high molecular weight polymers. Proteoglycans like hyaluronic acid are included in many cosmetic or parenteral products. Additionally, controlled release versions of parenteral formulations often include high molecular weight polymers. When it comes to non-aqueous solvents, oil-based product formulations tend to be the most viscous.

How is parenteral product viscosity calculated?

The United States Pharmacopeia offers three methods for viscosity determination. The first method is the viscosity-capillary viscometer approach (USP 911), which is the focus of this article. The second method is a rotational rheometer technique (USP 912). The rolling ball viscometer method (USP 913) is the third option for calculating viscosity.

How is viscosity calculated using the rotational rheometer method?

The rotational rheometer method is used to determine the viscosity for Newtonian and apparent viscosity for non-Newtonian fluids. Viscosity can be obtained from rotational rheometers through four different methods: spindle viscometers (Method 1), concentric cylinder rheometers (Method 2), cone-and-plate rheometers (Method 3), and parallel plate rheometers (Method 4). All four methods measure the force (torque) acting on a rotor when it rotates at a constant angular velocity (or rotational speed) in a liquid. As viscosity depends on temperature, the temperature of the samples measured should be controlled to within ±0.1°C when evaluated. Additional details on each rotation rheometer method are described below.

Method 1: Spindle Viscometers

For a spindle viscometer, the apparent viscosity is determined by rotating a cylinder-shaped or disk-shaped spindle in a large volume of liquid. An example of a disk-shaped spindle is depicted in Figure 1.

The torque to maintain a given angular velocity for the spindle viscometer measures the liquid resistance to flow (apparent viscosity). Spindle viscometers cannot calculate absolute viscosity with a large gap between the spindle and the container wall or with spindles of a certain geometry. Follow the spindle viscometer manufacturer’s recommendations regarding spindle selection and viscometer operation.

When viscosity measurement is performed in a beaker or cup, the following parameters must be reported along with the measured viscosity:

- Size and geometry of spindle

- Angular velocity or rotational speed of the spindle

- Temperature of the test substance

When using a spindle viscometer, the spindle should be immersed to the manufacturer’s recommended depth and maintain at least one centimeter of clearance from the bottom and sides of the container. A spindle viscometer is calibrated if the apparent viscosities it measures are within 5% of the known Newtonian viscosity standards.

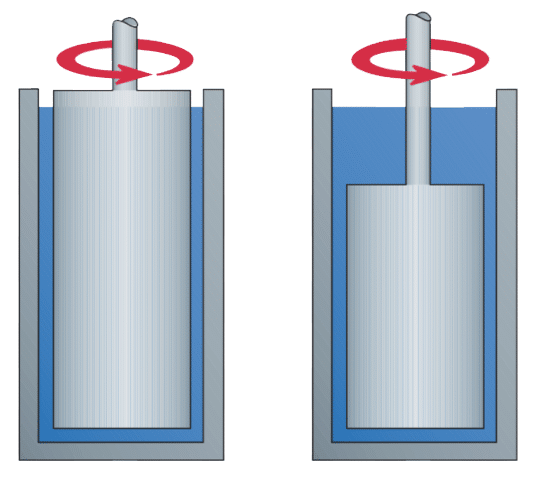

Method 2: Concentric Cylinder Rheometers

For a concentric cylinder rheometer, the apparent viscosity is measured by placing the liquid sample in a gap between the inner cylinder and the outer cylinder of the rheometer. In these rheometers, either the outer cylinder (the cup) or the inner cylinder (the bob) rotates. Rotating-cup rheometers are known as Couette systems, while rotating-bob rheometers are called Searle systems. Controlled-stress and controlled-rate concentric cylinder rheometers are available with absolute geometries (e.g., tiny annular gaps between concentric cylinders) that allow the calculation of apparent viscosities for non-Newtonian fluids. Controlled shear stress rheometers measure the shear rates from the application of a given force or torque (stress). Whereas controlled shear rate rheometers measure the shear stress (the torque on the rotor axis) resulting from a given shear rate (rotational speed).

Variables for calculation of viscosity with concentric cylinder rheometers are:

M = torque acting on the cylinder surface in Newton x meter (N x m)

R0 = radius of the outer cylinder meters (m)

R1 = radius of the inner cylinder (m)

h = height of immersion of the inner cylinder in the liquid medium (m)

ω = angular velocity (radians per second)

η = viscosity (Pascal x second)

v = velocity in meters per second(m/s)

To test a sample with a concentric cylinder rheometer, place the test fluid in the rheometer and allow the sample to reach thermal equilibrium. Then follow the manufacturer’s procedure for the rheometer’s operation. For non-Newtonian fluids, use the appropriate type of rheometer based on manufacturer recommendations. Then determine apparent viscosities by changing the shear rate (or shear stress). A series of viscosity measurements can measure the relationship between the shear rate and the shear stress of the non-Newtonian liquid.

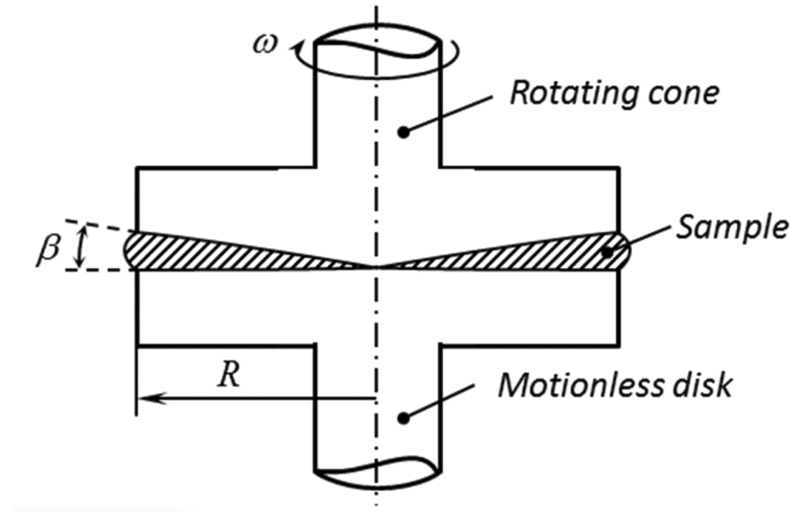

Method 3: Cone-and-Plate Rheometers

For a cone-and-plate rheometer, the sample liquid is placed into a fixed gap between a flat disk (or plate) and a cone forming a defined angle (ß). The cone’s angle keeps a constant shear rate due to the increase in both the gap between the cone and the plate as the distance increases from the origin. Viscosity measurements can be performed by either rotating the cone or rotating the plate. As the sample volume for cone-and-plate rheometers is small, even a tiny loss of the solvents can cause a significant change in the measured viscosity. Thus, precautions must be taken when measuring sample viscosities, especially for samples with volatile solvents. The overall process for testing a sample with a cone-and-plate rheometer is comparable to the process used for concentric cylinder rheometers. Please see the concentric cylinder rheometer section if looking for additional details on the process for this methodology.

Important variables for cone-and-plate rheometer calculations are:

ω = angular velocity (radians/s)

M = torque acting on the flat plate or cone surface (N x m)

ß = angle between the flat plate and cone (radians)

R = radius of the cone (m)

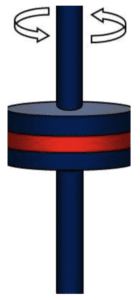

Method 4: Parallel Plate (Parallel Disk) Rheometers

Parallel plate rheometers are similar to cone-and-plate rheometers. The difference between parallel plate rheometers is that the sample to be measured is introduced into the gap between a flat plate or disk and another parallel flat plate or disk. Generally, measurements with a parallel plate rheometer are made by keeping the lower plate or disk stationary as the upper plate or disk is rotated at a constant angular velocity, ω.

Critical variables for parallel plate rheometer calculations are:

ω = angular velocity (radians per second)

R = radius of the plate in meters (m)

h = distance between the two parallel plates (m)

Different from the cone-and-plate rheometer, the shear rate between parallel plates increases as you move away from the origin of the axis of rotation. Shear rate increases away from the origin of the axis of rotation because of the increasing speeds for angular velocity with a constant gap. Advantages of the parallel plate rheometer include ease of sample loading for very viscous liquids and its suitability for determining the viscosity of particulate suspensions. If a suspension is assessed, the gap should be set high enough to avoid grinding particles between the parallel plates. In the absence of large particles, the parallel plates may be used at narrower gaps. Like cone-and-plate rheometers, the evaporative loss of a solvent can significantly affect the sample’s measured viscosity. Thus, precautions need to be taken to minimize solvent loss. The overall process for processing a sample with a parallel plate rheometer is comparable to the methods used for concentric cylinder rheometers. Please see the concentric cylinder rheometer section if looking for additional details on the process for this methodology.

Summary

Overall, viscous injectable formulations often have high concentrations of large molecules or non-aqueous solvents. With large protein biologics popularizing the drug therapy market, viscosity calculations for viscous products are essential for determining delivery mechanisms and accurately filling parenteral products. The rotational rheometer method of viscosity calculation is one of three techniques described in the United States Pharmacopeia for determining viscosity. Unlike capillary and rolling ball viscometry, which only calculate viscosity for Newtonian fluids, rotational rheometers can calculate viscosity for Newtonian fluids and apparent viscosity for non-Newtonian fluids. There are four ways to determine viscosity through rotational rheometers. These four ways are through using spindle viscometers (Method 1), concentric cylinder rheometers (Method 2), cone-and-plate rheometers (Method 3), and parallel plate rheometers (Method 4). All in all, when filling a thick parenteral or cosmetic product, ensure you choose a contract manufacturing organization to support your sterile filling needs.

MycoScience is a contract manufacturing organization specializing in sterile syringe and vial filling. MycoScience also offers Preservative Efficacy Testing, Sterilization Validations, Bioburden Testing, Cleaning Validations, Microbial Aerosol Challenge Testing, Accelerated Aging, Microbiology Testing, Cytotoxicity Testing, Bacterial Endotoxin Testing, EO Residual Testing, Package Integrity Testing & Environmental Monitoring services medical devices and allied industries. MycoScience is an ISO 13485 certified facility.

References

Michael J. Akers. Sterile Drug Products Formulation, Packaging, Manufacture, and Quality. Drugs and the Pharmaceutical Sciences. Informa Healthcare. 2010.

Andrew Donnelly. Injecting High Viscosity Drugs: Challenges and Solutions. Bespak.com

Andy Fry. Injecting Highly Viscous Drugs. Pharmaceutical Technology. 2021.

Sharing this in your social netwroks