Preservative Efficacy Testing Vs. Bioburden Testing

What are preservatives?

Preservatives are substances mixed into creams, gels, and other liquids. Preservatives are used to prevent the growth of bacteria, fungi, and other microorganisms within a medical, cosmetic, household, or food product. Preservatives also help keep the freshness of the appearance of a product and keep its consistency intact over time. USP preservative efficacy tests assess the functionality of preservatives in products and determine the microbial bioburden a preservative can withstand. Microbial bioburden testing (bioburden test USP) is separate from preservative efficacy testing. Learn more about preservative efficacy test protocol, FDA guidance and bioburden testing below.

What is preservative efficacy testing (PET)?

USP preservative efficacy testing, also known as preservative challenge testing, determines the effectiveness of a preservative during its shelf life and evaluates how well a product withstands microbial contamination during use.

What Is bioburden?

The “bio” in bioburden refers to live biological organisms, and the “burden” in bioburden refers to the concentration of the viable biological organisms. Thus, bioburden is the concentration or quantity of microorganisms in a given area or from a particular sample. The higher the concentration of viable microorganisms on a device or product, the higher the burden is to kill those organisms, whether it is killing the organisms through sterilization procedures or killing the organisms through the effort of the human immune system.

What is bioburden testing?

What products require preservative efficacy testing?

Preservative efficacy testing can be used to determine the best preservative to use in your topical formulation and the minimum effective concentration needed to preserve the pharmaceutical, food, or biotechnology product being assessed. Topical formulations (gels, creams, ointments, and lotions) comprise a water or oil base that delivers various medications, natural substances (such as herbs), or moisture through the skin. Topical cosmetics contain preservatives to support the stability of the formulation and prevent microbial growth during repeated product use. Preservative challenge testing is also used for parenteral products containing multiple doses. In these products, antimicrobial preservatives inhibit the growth of any microorganisms introduced during repeated insertion and withdrawal to load individual amounts.

USP bioburden testing (bioburden test USP) measures the viable organisms present in a sample. The total viable organisms present is expressed as a total viable count. This total viable count (expressed as colony-forming units) quantifies the microbial contamination level within a particular sample. Combined bioburden and microbiology testing can identify what types of live microorganisms are present in a sample from a product, package, or manufacturing environment. Bioburden testing may be referred to synonymously with microbiology testing. However, microbiology testing is a broader field of microbial assessments. Bioburden testing follows the methods outlined in USP 60, USP 61, and USP 62.

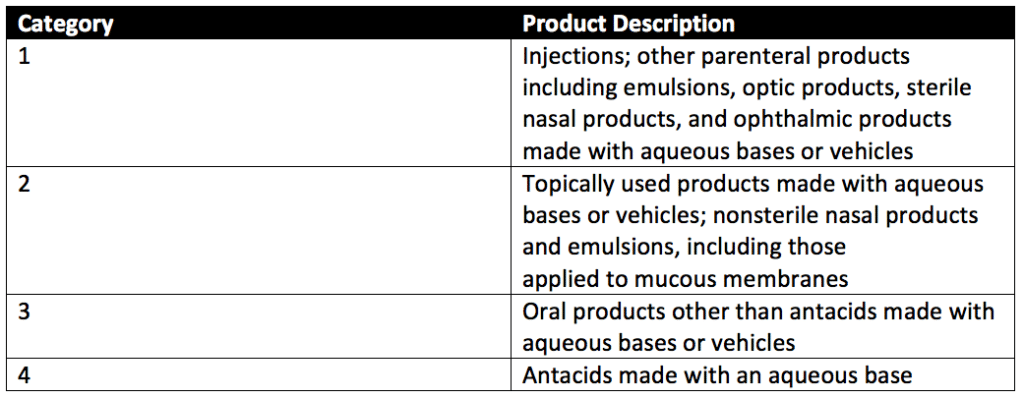

Preservative efficacy test protocols can evaluate four categories of products with preservative challenge testing. These product categories are detailed in Table 1 of USP 51, reproduced below.

What products require bioburden testing?

FDA guidance and bioburden testing is an important quality control step that detects the level of contamination of a product at any stage, from initial product manufacture to final distribution. As microorganisms exist on every surface (including our body), bioburden can be accidentally introduced during the manufacturing or packaging process in many ways. Some of the most common examples are contamination through the raw materials used, technicians, tubing/piping used to transfer product between development stages in a process, or the manufacturing environment itself. With such abundant sources of contamination, regular FDA guidance and bioburden testing of all sterile products reduces microbial contamination and recall risks. FDA guidance usually points to USP guidances for bioburden testing. Thus, USP bioburden testing should cover all FDA guidance requirements.

How is preservative Efficacy testing performed?

Preservative efficacy test protocols have three approaches. Preservative efficacy test protocols come from the Schülke KoKo Test, United States Pharmacopeia (USP), and the European Pharmacopeia.

Schülke KoKo Test Vs. U.S. Pharmacopeia Vs. European Pharmacopeia

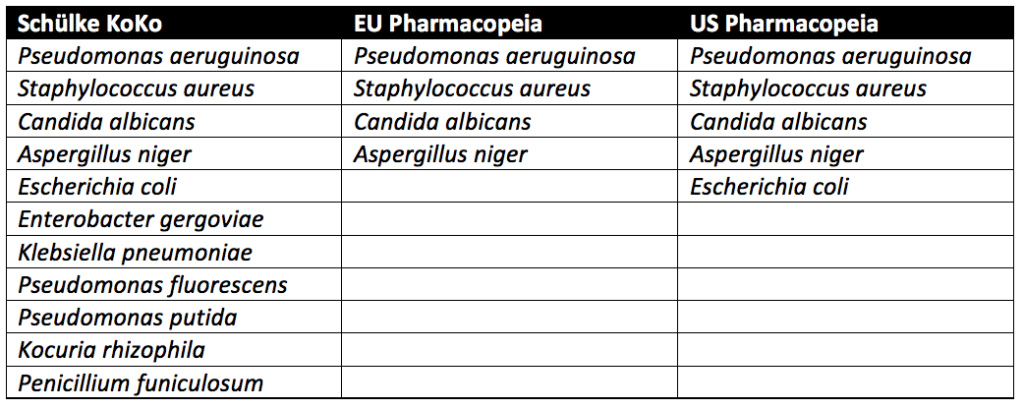

Pseudomonas aeruginosa, Staphylococcus aureus, Aspergillus niger, and Candida albicans must be tested for in all cosmetic products sold in the European Union. In addition to the microbes above, testing with microbes known to lead to spoilage of cosmetic products is recommended but not required. In the United States, the USP guidelines require testing of Escherichia coli in addition to Pseudomonas aeruginosa, Staphylococcus aureus, Aspergillus niger, and Candida albicans. Spoilage microbes are not needed for PET. In contrast to the pharmacopeia tests, which only evaluate pathogenic microbes, the Schülke KoKo test evaluates product spoiling microorganisms. Schülke KoKo test’s spoiling microorganisms are based on decades of cosmetic testing experience from Schülke & Mayr in Germany.

USP preservative efficacy test protocols evaluate cosmetic products by exposing them to a single microbial strain at a time. Additional details on USP preservative challenge testing, which follows similar procedures to the European Pharmacopeia, can be found through reading our articles on Preservative Challenge Testing And USP 51 and Preservative Efficacy Testing For Medical Devices. In contrast, for the Schülke KoKo test, the single cultivated microbes are brought together into a mixed suspension to challenge the cosmetic product. A new mixed suspension is prepared for each of the six inoculation cycles for Schülke KoKo testing. Since the Schülke KoKo test uses a mixed microbe inoculation, it simulates microbial exposure of a product during production, filling, and use. Indeed, a product would likely be exposed to multiple microbes at once instead of one at a time. Overall, though different from the USP and European Pharmacopeia methods, the Schülke KoKo Test is a reliable test method for assessing the efficacy of antimicrobial preservation of cosmetic products.

First, cultures of Candida albicans (ATCC No. 10231), Aspergillus brasiliensis (ATCC No. 16404), Escherichia coli (ATCC No. 8739), Pseudomonas aeruginosa (ATCC No. 9027), and Staphylococcus aureus (ATCC No. 6538) are prepared. Stock cultures of these organisms are prepared by centrifuging an ATCC culture removing residual media from the prior culture and resuspending the microorganisms in a sterile suspension fluid. The suspension fluids for each microorganism referenced above are prepared at a microbial count of about 1 × 108 colony-forming units per milliliter (CFU/mL).

Preservative efficacy testing is performed in five sterile, capped containers. Suppose the product’s original container is sterile, can be entered aseptically, and holds an appropriate product volume. In that case, the original filled product containers may be used. Each of the five product samples is injected with a test suspension of either Candida albicans, Aspergillus brasiliensis, Escherichia coli, Pseudomonas aeruginosa, or Staphylococcus aureus. Each product sample is exposed to only a single microbe of the five listed, and all microbes are exposed to the product during testing. The microbial test suspension injected is between 0.5%- 1% of the volume of the product under assessment and is at a concentration of 1 × 105 and 1 × 106 CFU/ml of the product for category 1-3 products. The final concentration per ml of category 4 products is between 1 × 103 and 1 × 104 CFU/mL.

Each of the five product samples with their respective microbial injections is incubated at a simulated room temperature of 22.5 ± 2.5°C or 32.5 ± 2.5°C depending upon the microbe the product sample is exposed. Microbial counts are taken at 7, 14, and 28 days for most microorganisms tested. The plate-count method determines the number of CFU present in each inoculated product sample. This plate-count method is completed in duplicate. Once all counts are taken, the change in log10 of the concentration of CFU/ml is calculated for each microorganism. The requirements for antimicrobial effectiveness are met if no increase in microbial growth for the various organisms tested occurs within the timeframes specific to each organism. are met. No increase in microbial growth is defined as not more than 0.5 log10 units more than the previous microbial growth value.

How are bioburden tests performed?

Microbiology and bioburden testing methods overlap. Both microbiology and bioburden tests require sample collection from a product, a surface, a water source, or the air. Once samples are obtained, the microbial content (bioburden) can be quantified. Below are links to articles related to multiple microbiology tests and testing methods. Bioburden microbial characterization methods can be found here, whereas the top techniques for microbiology examination are here. A comparison between USP 60, USP 61, and USP 62 bioburden testing regulations can be found here.

What are the differences between preservative efficacy testing and bioburden testing?

Preservative challenge testing determines the best preservative for use and the minimum effective concentration needed to preserve multidose parenteral products, topicals products, food, or other healthcare items that contain preservatives. In contrast, bioburden testing quantifies the microbes within an environment or a product. Both preservative and bioburden tests are quantitative examinations. Further, microbial counting methods for both tests are similar. However, preservative challenge testing evaluates a product’s antimicrobial properties, while bioburden testing supports the environmental monitoring and sterility assurance of products.

Summary

Overall, preservative challenge testing and bioburden testing are imperative for regulatory approval of pharmaceutical/cosmetic preservatives and product sterility, respectively. Preservative efficacy testing evaluates injectables, topicals, orals, and antacids made with an aqueous base for their antimicrobial activity. In contrast, bioburden testing evaluates the microbial levels of products and manufacturing environments at various phases during production and packaging. Bioburden content supports microbial monitoring and controlling for sterilization and aseptic processes. All in all, ensure you choose a contract manufacturing organization that can support you with appropriate preservative efficacy and bioburden testing for your unique cosmetic, pharmaceutical, or medical product needs.

MycoScience is a contract manufacturing organization specializing in Preservative Efficacy Testing and Bioburden Testing. MycoScience also offers Sterilization Validations, Microbial Aerosol Challenge Testing,Cleaning Validations, Accelerated Aging, Microbiology Testing, Cytotoxicity Testing, Bacterial Endotoxin Testing, EO Residual Testing, Package Integrity Testing & Environmental Monitoring services medical devices and allied industries. MycoScience is an ISO 13485 certified facility.

References

Michael J. Akers. Sterile Drug Products Formulation, Packaging, Manufacture, and Quality. Drugs and the Pharmaceutical Sciences. Informa Healthcare. 2010.

United States Pharmacopeial Convention. <51> Antimicrobial Effectiveness Testing. Rockville, MD, USA. 2021. (USPC <51>).

United States Pharmacopeial Convention. <60> Microbiological Examination of Nonsterile Products- Tests for Burkholderia Cepacia Complex. Rockville, MD, USA. 2021. (USPC <60>).

United States Pharmacopeial Convention. <61> Microbiological Examination of Nonsterile Products: Microbial Enumeration Tests. Rockville, MD, USA. 2021. (USPC <61>).

United States Pharmacopeial Convention. <62> Microbiological Examination Of Nonsterile Products: Tests For Specified Microorganisms. Rockville, MD, USA. 2021. (USP <62>).

Sharing this in your social netwroks