Top 3 Delivery Options For Viscous Parenteral Products

What is Viscous friction?

Viscosity is the amount of internal friction (or internal resistance) between components in a fluid. Honey is an everyday example of a highly viscous fluid (a product with viscous friction). Products with high viscosity are considered “thick” and flow slowly. In contrast to viscous liquids, water is an example of a fluid with low viscosity. Products with low viscosity are considered “thin” and flow quickly and easily. A fluid’s flow speed depends on how fast the molecules in a fluid can rearrange and move past each other. Thus, liquids with small molecules tend to have low viscosity (less viscous friction). Liquids with long-chain molecules (such as hyaluronic acid) have higher viscosity (high viscous friction). Also, liquids with molecules that can form bonds with each other are more viscous (very high viscous friction). The bonding of glucose and fructose in honey is why honey is so viscous. Many viscous products may require needle-free delivery systems.

What are viscous Liquids?

Viscous fluid formulations (viscous liquids) often have high concentrations of large molecules or non-aqueous solvents. Highly viscous formulations contain both. Examples of large molecules include monoclonal antibodies, proteoglycans, and high molecular weight polymers. Proteoglycans like hyaluronic acid are included in many cosmetic or parenteral products. Additionally, controlled release versions of parenteral formulations often include high molecular weight polymers. When it comes to non-aqueous solvents, oil-based product formulations tend to be the most viscous. Viscous liquids can be challenging to fill. However, you can learn how to overcome difficulties with viscous fluid filling HERE.

What are the top three Administration options for viscous Fluids?

#1: Auto-Injector Technologies

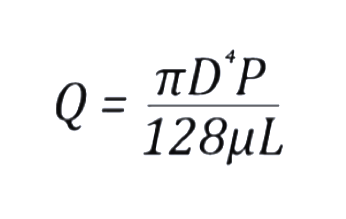

For syringes, the needle’s diameter and the viscosity of the solution determine how hard you need to push on a plunger for the drug to be administered. The force or effort required to move a drug through a syringe is known as syringeability. For a conventional hypodermic syringe and needle, syringeability can be calculated using the Hagen-Poiseuille equation, where Q=flow rate, D= needle bore, L=needle length, P=drive pressure, µ=dynamic viscosity.

Generally, the more viscous the solution, the larger the needle gauge required for the injection. The downside of a larger needle is increased pain for the patient during the injection. Approaches such as using thin-walled or tapered needed to reduce viscous resistance will not overcome the large force needed for viscous preparations. Thus, for highly viscous solutions, autoinjectors are required to support the injection process. However, traditional, spring-based autoinjectors struggle to deliver product formulations with viscosities as low as 20cP. The limitations of spring-based autoinjectors lead to needle breakages and autoinjector malfunctions. Luckily, newer technologies, such as the Bespak VapourSoft®, can deliver viscous formulations in the 1000’s of cP through relatively fine needles. Unlike spring-based autoinjectors, technologies like VapourSoft yield higher pressure to power drug delivery through a fine needle without risking syringe breakage. This higher pressure is provided by using liquefied gas as the power source instead of a spring. Additional details about VapourSoft technology and its devices can be found here.

#2: Large-Volume Injectors

Large-volume injectors are also known as bolus delivery devices. For large-volume injectors, injection time can be an opportunity instead of an obstacle. When applying the Hagen-Poiseuille equation for an autoinjector, a flow rate of ten seconds is an acceptable operating time for a patient receiving a traditional injection. However, if the injection device is worn for fifteen minutes during delivery, the flow rate and plunger force for the same injection volume will reduce by nine thousand percent. With large-volume injectors, the drug formulation is diluted to a larger volume of 5mL or more and delivered to the patient over an extended time. The therapeutic formulation dilution has the bonus of reducing the viscosity for viscous formulations, making the flow rate and force to deliver the product reasonable. Large-volume injectors use a variety of power sources and control mechanisms based on electrical, mechanical, and hybrid mechanisms. Materials for these devices fall within traditional delivery devices, mainly glass and plastics.

#3: Needle-Free Delivery

Needle-free delivery uses a high-velocity jet generated by driving liquid through a hole at high pressure to pierce the skin and underlying tissues. Needle-free delivery provides several advantages. Some of these advantages include therapy dose reduction due to intradermal delivery efficiencies, intradermal delivery reliability, elimination of needle stick, elimination of accidental needle re-use, and advantages of delivery for viscous fluids.

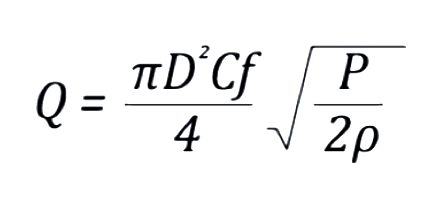

Since needle-free injectors deliver products through a hole instead of a tube, product flow is characterized by the Bernoulli equation below, where Q=flow rate, D= orifice bore, P=drive pressure, ρ=density, Cf=flow coefficient.

Notice that density is a component in the Bernoulli equation but that there is no viscosity term. Drug formulations often have densities close to that of water. Thus, needle-free devices can deliver the same product volume at the same rate, using the same energy, regardless of the product viscosity.

Summary

Overall, viscous injectables often have high concentrations of large molecules or non-aqueous solvents. With large protein biologics popularizing the drug therapy market, delivery methods for viscous products have become essential to those creating biological therapeutics. The top three options for delivery of viscous injectables are autoinjectors, large-volume injectors, and needle-free delivery. When filling a thick parenteral or cosmetic product, ensure you choose a contract manufacturing organization to support your sterile filling needs.

MycoScience is a contract manufacturing organization specializing in sterile syringe and vial filling. MycoScience also offers Preservative Efficacy Testing, Sterilization Validations, Bioburden Testing, Cleaning Validations, Microbial Aerosol Challenge Testing, Accelerated Aging, Microbiology Testing, Cytotoxicity Testing, Bacterial Endotoxin Testing, EO Residual Testing, Package Integrity Testing & Environmental Monitoring services medical devices and allied industries. MycoScience is an ISO 13485 certified facility.

References

Michael J. Akers. Sterile Drug Products Formulation, Packaging, Manufacture, and Quality. Drugs and the Pharmaceutical Sciences. Informa Healthcare. 2010.

Andrew Donnelly. Injecting High Viscosity Drugs: Challenges and Solutions. Bespak.com

Andy Fry. Injecting Highly Viscous Drugs. Pharmaceutical Technology. 2021.

Sharing this in your social netwroks