Why is sterile fill & finish outsourcing so popular?

What are fill and finish operations?

Fill and finish operations enable a product to be filled and sealed into end-use containers with appropriate sterility and precision. Fill and finish processes are particularly important for filled vials, syringes, cartridges, and other medical-grade products so that the correct quantity of sterile and contaminant-free product is added and sealed consistently.

Why are biopharmaceutical fill and finish processes often outsourced to contract manufacturers?

The combination of filling and finishing operations is one of the most commonly outsourced biopharmaceutical manufacturing activities due to the equipment, cleanrooms, and trained staff needed for such specialized tasks. Indeed, the final formulations for medical-grade cosmetics, biopharmaceuticals, and other medical-grade products require special handling and protocols to ensure their sterility and safety when filled into their final product containers. Inappropriate, in-house filling for biological products and pharmaceutical products made from high-cost raw materials (or processes) are costly to correct and not worth the risk for most pharmaceutical and medical device companies. Neither is the financial burden of purchasing specialized equipment and hiring trained staff just for filling one product.

What are the current trends in outsourced fill and finish processes?

#1: More filling and finishing manufacturers are utilizing single-use and disposable equipment

One of the top trends in sterile fill and finish activities is the increase in single-use or disposable equipment to reduce cleaning requirements and reduce cross-contamination during filling. For example, single-use filters, connectors, and manifolds can lower contamination risks and minimize processing downtime.

#2: The outsourcing of filling and finishing activities ubiquitous

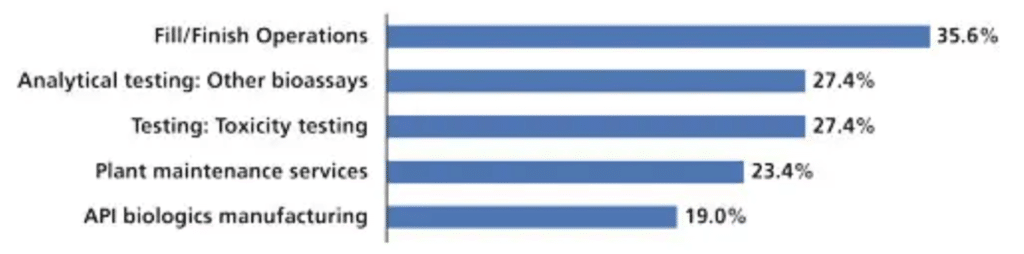

Almost 75% of biomanufacturers outsource filling and finish activities to some degree. Further, filling and finishing processes rank fourth out of the top twenty-four outsourced biomanufacturing activities, outranking toxicity testing.

#3: An increase in automation for filling and finishing activities

As human interaction is one of the top contamination risks during any manufacturing process, most aseptic filling activities are highly automated. Automated activities include raw materials loading, system changeovers (such as those needed for prefilled syringes), and cleaning. Robotics and advances in automation allow even more processes to be automated and altered with efficiency and ease.

Why should companies consider outsourcing filling and finishing processes?

Sterile filling and finishing activities require specialized staff, expensive automated equipment purchases, and cleanroom set-up, monitoring, and certifications. Further, each filling and finishing task requires specialized protocols, equipment, and staff training. Thus, it is much more effective to outsource sterile filling and finishing processes for most products than to spend the money on an in-house system. Indeed, it does not make financial sense to purchase equipment for a single prefilled syringe, cartridge, vial, device, or lyophilized product. Further, contract manufacturing companies have the experience and capital to easily adopt more sophisticated filling techniques and invest in newer technologies as they arrive, compared to in-house operations. Thus, contract manufacturing companies offer products filled faster, safer, and more effectively than in-house operations.

Summary

Overall, filling and finishing operations enable a product to be filled and sealed into end-use containers with appropriate sterility and precision. Fill and finish operations are particularly important for filled vials, syringes, cartridges, and other medical-grade products so that the correct quantity of sterile and contaminant-free product is added and sealed consistently. Filling and finishing activities and operations are the fourth most heavily outsourced biomanufacturing activity, and the outsourcing of these activities is only expected to remain steady or grow over time. Companies outsource filling and finishing activities because fill/finish activities require specialized staff, expensive automated equipment purchases, and cleanroom set-up, monitoring, and certifications. Further, each filling and finishing task requires specialized protocols, equipment, and staff training. Thus, it is much more effective to outsource sterile filling and finishing processes for most products than to spend the money on an in-house system. All in all, if you are outsourcing your filling and finishing processes, ensure you choose a contract manufacturing organization that can support you with your unique filling and finishing needs.

MycoScience is a contract manufacturing organization specializing in sterile syringe and vial filling cosmetic products or for products used in animal studies. In addition, MycoScience offers testing services, including Preservative Efficacy Testing, Cytotoxicity Testing, Bioburden Testing, Cleaning Validations, Microbial Aerosol Challenge Testing, Accelerated Aging, Microbiology Testing, EO Residual Testing, Bacterial Endotoxin Testing, Package Integrity Testing, Sterilization Validations & Environmental Monitoring services medical devices and allied industries. MycoScience is an ISO 13485 certified facility.

References

2016. Langer, “Fill/Finish Outsourcing,” BioPharm International 29 (10) 2016.

Michael J. Akers. Sterile Drug Products Formulation, Packaging, Manufacture, and Quality. Drugs and the Pharmaceutical Sciences. Informa Healthcare. 2010.

Sharing this in your social netwroks