How to perform disinfectant challenge testing for cleaning validations

What is a disinfectant?

A disinfectant is an agent (chemical or physical) that kills or removes harmful microorganisms when applied to a surface.

What are disinfectants used for, and why are they important?

Validated cleaning and sanitization processes are needed for cleanrooms and other controlled manufacturing environments to prevent microbial contamination of medical and pharmaceutical products. Microbial contamination can occur in various ways during device and drug manufacture. Primary sources of microbial contamination risk include raw ingredient sources, process water, packaging components, processing equipment, and manufacturing operators. Thus, appropriate environmental monitoring that follows current Good Manufacturing Practice (cGMP) is vital to keeping potential contamination risk for health care products and devices low. GMP cleaning and sanitization programs apply to both sterile and nonsterile products.

Disinfectants are used to keep manufacturing environment surfaces free from harmful contaminants. Disinfectants may be used on floors, walls, and ceilings. Each disinfectant has a certain bactericidal (bacteria-killing), fungicidal (fungi-killing), and sporicidal (bacterial spore-killing) efficacy. Agents that kill bacteria and spores are particularly good at preventing large-scale bacterial growths known as biofilms. Disinfectant selection is based on the bacterial, fungi, and spore risk of the manufacturing area where the disinfectant will be used. In addition to its microbe-killing profile, a disinfectant should keep the drug product or device under manufacture in mind and should not be harmful to the drug chemistry, drug toxicity, or device materials. Disinfectants are inherently toxic, so drug products must be protected from exposure to most disinfectants used.

What types of chemical disinfectants are available?

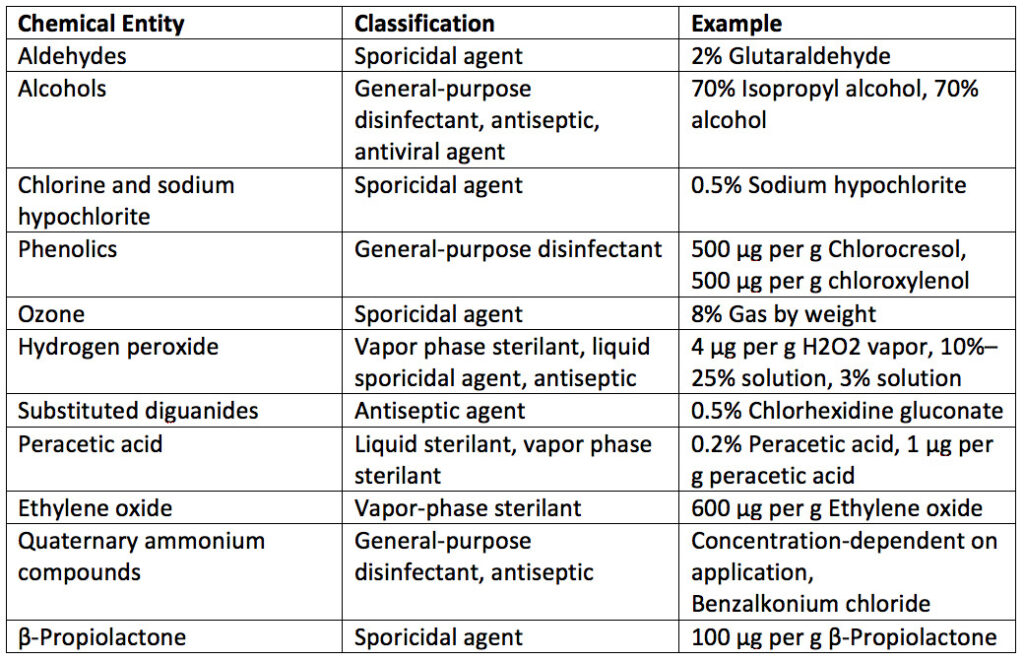

Chemical disinfectants are labeled by their chemical type. Examples of disinfectant chemical families are listed in Table 1. Note that types and ratios of chemicals used as disinfectants are also detailed in Table 1. For ratios of chemicals, “μg per g” is microgram per gram.

A disinfectant’s effectiveness depends on its natural biocidal activity. Additionally, a disinfectants ability to kill microbes depends on its concentration, contact time with the surface, the type of surface disinfected, the hardness of the water used for dilution, the quantity of organic material present on the surface, the types of microbes present, and the number of microorganisms populating the surface. Due to the various factors that can influence how well a disinfectant agent works, the Environmental Protection Agency (EPA) registers chemical disinfectants marketed in the United States and requires manufacturers to provide use dilution and required contact time to kill microbes of interest. Some liquid or gas chemical sterilizers used on critical or semi-critical medical devices are defined and regulated by the United States Food and Drug Administration (FDA). One of these chemical sterilizers is ethylene oxide.

How is disinfectant challenge testing performed?

The EPA requires companies that register disinfectants to ensure the safety and effectiveness of their products before they are sold. Thus, EPA registered disinfectants must have toxicology data available for the chemical composition of their product to prove that it is safe when used as directed on the label. Further, EPA registered disinfectants must also have efficacy data to prove that their product is effective against the organisms they claim to kill. However, these EPA validated disinfectants, and their directions, are not sufficient for use in GMP manufacturing for pharmaceutical, biotechnological, and medical device industries. Indeed, the EPA does not address how disinfectants are used in these environments. Thus, official disinfectant testing must be performed for disinfectants used in manufacturing environments so that these disinfectants meet aseptic and non-aseptic manufacturing cleaning validation criteria. In the United States, the official disinfectant testing methods are the phenol-coefficient test, use-dilution method test, hard surface carrier method, and sporicidal carrier test.

A disinfectant used in a pharmaceutical manufacturing environment would undergo the following tests:

- Use-dilution tests: screen disinfectants for their efficacy (at various concentrations and contact times) against a wide range of standard test organisms and environmental isolates

- Surface challenge tests: use standard test microorganisms based on typical environmental isolates and apply disinfectants to surfaces at predetermined concentrations with a specified contact time.

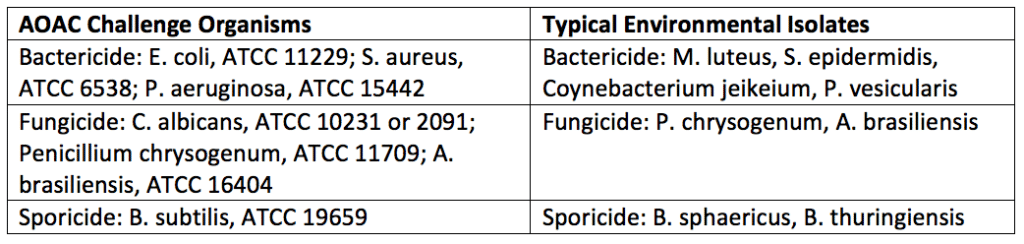

After use-dilution and surface challenge testing has been performed, a statistical comparison (log reduction) of the numbers of microorganisms isolated before and after disinfection would be completed. Test organisms are counted using swabs, surface rinse, or contact plate methods in surface challenge tests. As a control, neutralizers that inactivate the disinfectants should be included in either the diluent or microbiological media used for microbe counting. For acceptance criteria, enough organisms need to be killed or removed on a 2-inch × 2-inch square of the surface being decontaminated. Generally, a 2-log reduction (for bacterial spores) or a 3-log reduction (for vegetative bacteria) will need to be accomplished during a predetermined contact time (i.e., 10 minutes). Disinfectants are less effective against the higher numbers of microorganisms used in challenge tests and more effective against the numbers found in clean rooms. Further, the organisms typically used in laboratory tests are more resistant (except for spores) than those used in laboratory tests found in an actual manufacturing environment. Thus, disinfectant challenge tests are robust, and disinfectants that pass these criteria will be more than capable of disinfecting the actual manufacturing area they are selected for. Typical challenge organisms that may be used for disinfectant testing are listed in Table 2 below.

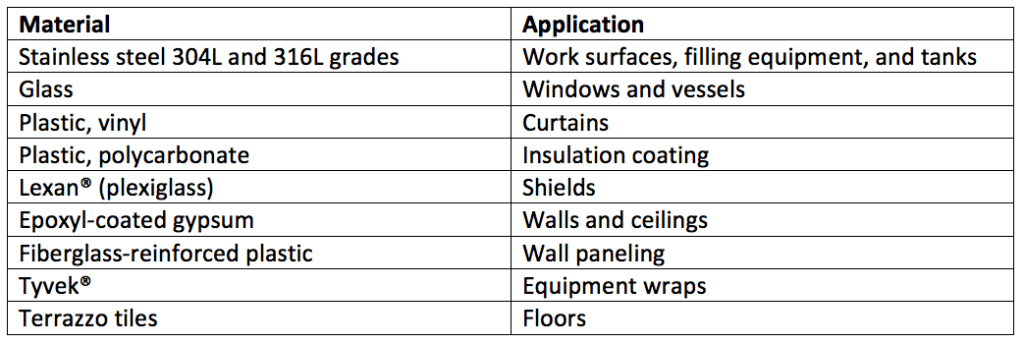

Cleanroom construction isn’t uniform. Thus, each material within the cleanroom and other controlled areas must be evaluated separately to validate the efficacy of a given disinfectant used on its surface. Table 3 is a list of common materials used in cleanroom construction.

Summary

Overall, validated cleaning processes are needed for cleanrooms and other controlled manufacturing environments to prevent microbial contamination of medical devices, products, and drugs. Disinfectants are used to keep manufacturing environment surfaces free from harmful contaminants. Each disinfectant has a certain bactericidal (bacteria-killing), fungicidal (fungi-killing), and sporicidal (bacterial spore-killing) efficacy. A series of disinfectant tests must be performed on disinfectants before they can be used in manufacturing environments. In the United States, the official disinfectant testing methods are the phenol-coefficient test, use-dilution method test, hard surface carrier method, and sporicidal carrier test. Typically, only use-dilution and surface carrier testing are necessary to prove a disinfectant’s efficacy. All in all, ensure you choose a contract testing organization that can provide appropriate cleaning validations for your unique medical device or product needs.

MycoScience is a contract manufacturing organization specializing in sterile syringe and vial filling. MycoScience also offers Preservative Efficacy Testing, Sterilization Validations, Bioburden Testing, Cleaning Validations, Microbial Aerosol Challenge Testing, Accelerated Aging, Microbiology Testing, Cytotoxicity Testing, Bacterial Endotoxin Testing, EO Residual Testing, Package Integrity Testing & Environmental Monitoring services medical devices and allied industries. MycoScience is an ISO 13485 certified facility.

References

United States Pharmacopeial Convention. <1072> Disinfectants And Antiseptics. Rockville, MD, USA. 2021. (USP <1072>)

Sharing this in your social netwroks