How to determine parenteral product viscosities for Newtonian fluids

Why is viscosity important for parenteral products?

Small volume parenteral products are injected intradermally, subcutaneously, intramuscularly, or intravenously. Fluid viscosity impacts the gauge of needle and plunger pressure needed to deliver the therapy to a patient. Products with high viscosity (high fluid thickness measurements) require specialized equipment for filling. Additionally, high viscosity products may require special equipment for patient therapy delivery. Luckily, there are ways to calculate the viscosity of your product. This article gives Newtonian fluid examples, fluid viscosity equations, and further explains Newtonian fluid viscosity.

What are Newtonian fluids?

A Newtonian fluid is a fluid where the stresses from fluid flow are linearly correlated to the strain rate. With Newtonian fluids, the viscosity (Newtonian fluid viscosity) is constant no matter the shear rate or applied shear stress experienced by the fluid. Examples of common Newtonian fluids used in parenteral products are water and mineral oil. Another Newtonian fluid example we use recreationally is alcohol. Most fluids of low molecular weight are Newtonian fluids. In contrast, high molecular weight fluids (such as suspensions and emulsions) are generally non-Newtonian.

How do you calculate Newtonian viscosity?

Viscosity is the measure of a fluid’s resistance to flow. The amount of flow resistance a fluid has is based on the internal molecular interacts of the fluid and the magnitude of the external stress applied to the liquid. Shear stress and shear strain are different. Shear stress is a force (or system of forces) per unit area, whereas the shear strain is deformation (i.e., a change in shape or size). Viscosity depends on temperature, so the temperature of the fluid measured should be controlled to within 0.1 of a degree. Typically, Newtonian viscosities are measured in pascal seconds (Pa*s).

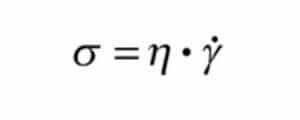

The coefficient of viscosity (absolute viscosity), η, is calculated with the following fluid viscosity equation based on Newton’s law of viscous flow:

Where:

σ = shear stress, the applied stress resulting in material layers to move relative to each other

γ = shear rate, the rate of change of shear strain with time

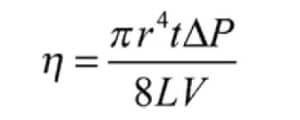

Viscosity (η ) can be calculated via the fluid viscosity equation above with a known fluid density with Poiseuille equation:

Where:

t= flow time

V= fluid volume

L=capillary tube length

ΔP= applied differential pressure

r= capillary tube radius

The applied pressure differential, ΔP, is calculated:

ΔP = (h1 − h2) × g × ρ (4)

Where:

ρ= fluid density

h1 = height of the fluid in the tube at line 1 measured from the bottom position

h2 = height of the fluid in the tube at line 2 measured from the bottom position

g = gravitational acceleration (standard value = 9.80665 m · s−2)

Kinematic viscosity, ν, can be calculated:

ν = k × t – (E/t2)

Where:

E = kinetic energy factor, in mm2 · s

k= viscometer constant

t= time (s)

For constants k and E, the flow time for a Newtonian liquid standard of known viscosity (at a given temperature) can be used to calculate the viscometer constant for that temperature. Calculated viscometer constants are accurate until the dimensions of the viscometer’s capillary change. All capillary viscometers can measure the viscosity of Newtonian fluids. However, most capillary viscometers are incapable of measuring the apparent viscosity of non-Newtonian fluids. As an exception, extrusion capillary viscometers allow for varying shear rate or shear stress and can be used to measure the apparent viscosities of non-Newtonian fluids.

How do you measure Newtonian viscosity with a rotational viscometer?

USP 912 details how to calculate Newtonian viscosity with a rotational viscometer. You can find calculations in our article on rotational viscometers here.

Summary

Overall, viscous injectable formulations often have high concentrations of large molecules or non-aqueous solvents. With large protein biologics popularizing the drug therapy market, viscosity calculations for viscous products are essential for determining delivery mechanisms and accurately filling parenteral products. A Newtonian fluid is a fluid where the stresses from fluid flow are linearly correlated to the strain rate. This article details calculations for the coefficient of viscosity (absolute viscosity) and the kinematic viscosity of Newtonian fluids. Most fluids of low molecular weight are Newtonian fluids. In contrast, high molecular weight fluids (such as suspensions and emulsions) are generally non-Newtonian. All in all, when filling a thick parenteral or cosmetic product, ensure you choose a contract manufacturing organization to support your sterile filling needs.

MycoScience is a contract manufacturing organization specializing in sterile syringe and vial filling. MycoScience also offers Preservative Efficacy Testing, Sterilization Validations, Bioburden Testing, Cleaning Validations, Microbial Aerosol Challenge Testing, Accelerated Aging, Microbiology Testing, Cytotoxicity Testing, Bacterial Endotoxin Testing, EO Residual Testing, Package Integrity Testing & Environmental Monitoring services medical devices and allied industries. MycoScience is an ISO 13485 certified facility.

References

United States Pharmacopeial Convention. <1911> Rheometry. Rockville, MD, USA. 2021. (USPC <1911>).

Sharing this in your social netwroks