How to determine parenteral product viscosities for non-Newtonian fluids

Why is viscosity important for parenteral products?

Small volume parenteral products are injected intradermally, subcutaneously, intramuscularly, or intravenously. Fluid viscosity impacts the gauge of needle and plunger pressure needed to deliver the therapy to a patient. Products with high viscosity require specialized equipment for filling. Additionally, high viscosity products may require special equipment for patient therapy delivery. Luckily, there are ways to calculate the viscosity or apparent viscosity of your product. Absolute viscosity is used for Newtonian fluids, while apparent viscosity is used for non-Newtonian fluids, such as an emulsion fluid. Additional information about apparent and absolute viscosity can be found HERE.

What is a Non-Newtonian Fluid vs. a Newtonian fluid?

A Newtonian fluid is a fluid where the stresses from fluid flow are linearly correlated to the strain rate. With Newtonian fluids, the viscosity is constant no matter the shear rate or applied shear stress experienced by the fluid.

In contrast, non-Newtonian fluids decrease (shear thinning) or increase (shear-thickening) viscosity when shear is applied. Most fluids of low molecular weight are Newtonian fluids. In contrast, high molecular weight fluids (such as suspensions and emulsions) are generally non-Newtonian. Shear-thinning occurs in water-based hydrocolloid solutions.

On the other hand, shear-thickening occurs in concentrated suspensions of nonaggregating solid particles (solid particles that don’t stick to each other in solution).

How do you calculate non-Newtonian viscosity?

Newton’s law of viscous deformation defines the relationship between applied stress, σ, and the resultant fluid flow with a shear rate (velocity gradient) of ̇γ. Suspensions or emulsions containing macromolecular components usually do not obey Newton’s law and require modifications to Newtonian laws, as detailed below. The equations below can be used to calculate non-Newtonian viscosity for fluid rheology that is not time-dependent. In other words, shear-thinning pseudoplastic and shear-thickening dilatant fluids may be calculated. However, rheopectic (time-dependent shear-thickening) or thixotropic (time-dependent shear-thinning) fluids will not be covered. While Newtonian fluid viscosity varies depending on temperature, non-Newtonian fluids have different viscosities depending on shear rate, shear stress, and temperature.

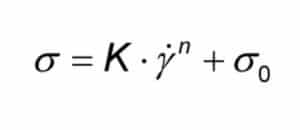

The Herschel–Bulkley equation can describe both Newtonian and non-Newtonian fluids:

Where:

σ = shear stress, in Pascals (Pa)

K = consistency coefficient (or the coefficient of viscosity in Pa*s)

̇γ = shear rate, in s−1

n = the flow behavior index

σ0 = yield stress, in Pa

For Newtonian fluids, K is the same as the coefficient of viscosity (η). As the viscosity of Newtonian fluid viscosity is independent of the shear stress or shear rate, the flow behavior index, n, is one for Newtonian fluids. The flow behavior index cannot be infinite. For shear-thinning fluids, the flow behavior index is greater than zero but less than one. Shear-thickening fluids have a flow behavior index of above one. Many non-Newtonian fluids do not have a yield stress of σ0 because the flow will occur even at very low shear stresses.

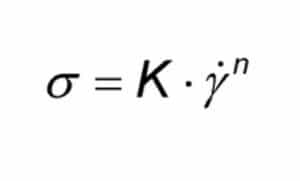

Without σ0, the Herschel–Bulkley equation reduces to the Ostwald–de Waele equation:

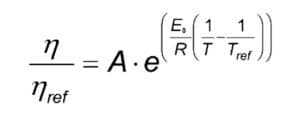

A modified Arrhenius equation can be used to characterize Newtonian and non-Newtonian flow as a function of temperature:

Where:

η = Newtonian or non-Newtonian viscosity at T

ηref = Newtonian or non-Newtonian viscosity at Tref

A = constant

E0 = energy for viscous flow

R = universal gas constant

T = absolute temperature

Tref = reference temperature

Energies for viscous flow and the constant A are found from experimental data. Viscous flow energy dissipation is a function of rheometer geometry, temperature control, shear rate, and shear stress.

Ultimately, there is no single viscosity for non-Newtonian fluids, like emulsion fluids, since viscosity values alter with the shear rate or shear stress. Thus, viscosity values calculated for non-Newtonian fluids are apparent viscosities. Apparent viscosities change depending on the shear rate, shear stress, and temperature conditions during viscosity measurement. Thus, temperature, shear rate, and shear stress values should be recorded along with apparent viscosity values. For non-Newtonian fluids, a rheogram (with apparent viscosity plotted on the y-axis and shear rate plotted on the x-axis) provides better fluid characterization for a product than a single apparent viscosity value. Each product will experience a unique set of shear rates and shear stresses during product manufacturing and use. Thus, ensure your rheograms measure the likely range of shear rates and shear stresses your parenteral product will encounter over its lifetime.

What is the difference between rheometers vs. viscometers, and which rheometer do you need to measure non-Newtonian fluids?

Viscometers are a subset of rheometers that only measure steady shear flow (and corresponding Newtonian viscosity). Viscometers are often referred to as relative rheometers. The functionality of relative rheometers is geometry-dependent. Thus, any non-Newtonian fluid data taken with a relative rheometer will be approximate and not comparable between rheological instruments. As a result, relative rheometers should not be used to evaluate non-Newtonian fluids. Instead, absolute rheometers should be used to create programs and assess non-Newtonian fluids. Absolute rheometers allow for geometrically accurate analysis of fluid deformation and flow. Thus, absolute rheometer data from non-Newtonian fluids can be compared from instrument to instrument.

How do you calculate viscosity using a rotational rheometer?

Rotational rheometers are prone to wall effects, where a thin, less-viscous layer of fluid (like emulsion fluids) develops at the wall of the instrument leading to inaccurate fluid measurements. Instrument manufacturers can provide wall effect corrections. The most common absolute rotational rheometers are concentric cylinders, cone-and-plate, and parallel-plate devices. Calculations for concentric cylinder and cone-and-plate rotational rheometers are detailed below. Information about rotational rheometers can be found HERE.

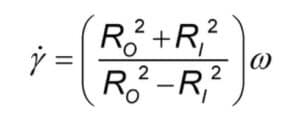

Using a concentric cylinder rheometer, how do you calculate the shear rate, shear stress, and apparent viscosity?

For non-Newtonian liquids, the shear stress, σ, or the shear rate, ̇γ, at which the viscosity is measured, must be recorded as viscosity values will vary based on the shear stress and shear rate experienced by the fluid. When considering parenteral products, the fluid’s anticipated shear stress or shear rate as it leaves a syringe needle or catheter would accurately determine the product’s viscosity when in use.

The following equations can be used to calculate the shear rate, shear stress, and viscosity when concentric cylinder rheometers satisfy absolute rheometer conditions (i.e., when the gap between the concentric cylinders is tiny).

Shear rate, γ, in s-1 is calculated:

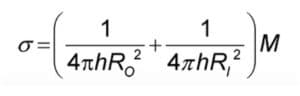

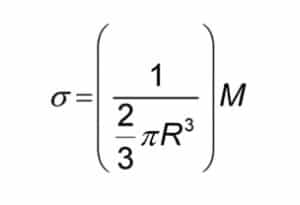

Shear stress, σ, in Pa is calculated:

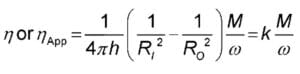

Apparent viscosity, η, in Pa*s is calculated:

Where:

Ro = radius of the outer cylinder (m)

RI = radius of the inner cylinder (m)

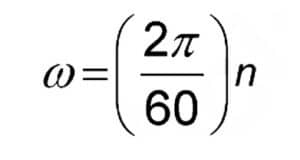

ω = angular velocity (radian/s)

M = torque acting on the cylinder surface (N . m)

h = height of immersion of the inner cylinder in the liquid medium (m)

k = constant of the apparatus (radians/m3)

And where angular viscosity is calculated using the following equation:

Where:

n = rotational speed, in revolutions per min (rpm)

How do you calculate the shear rate, shear stress, and apparent viscosity using a cone-and-plate rheometer?

The following equations can be used to calculate the shear rate, shear stress, and apparent viscosity (for emulsion fluids and the like) when cone-and-plate rheometers satisfy absolute rheometer conditions.

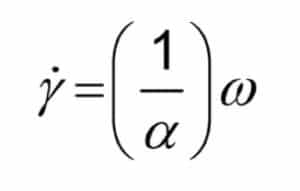

Shear rate, γ, in s-1 is calculated:

Shear stress, σ, in Pa is calculated:

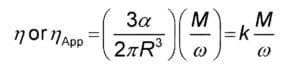

Apparent viscosity, η, in Pa*s is calculated:

Where:

α = angle between the flat plate and the cone (radians)

R = radius of the cone (m)

ω = angular velocity (radian/s)

M = torque acting on the cylinder surface (N . m)

k = constant of the apparatus (radians/m3)

How do you measure apparent viscosity using a nonrotational rheometer?

Slit rheometers and capillary-breakup elongational rheometers are examples of rheometers that do not rotate. These rheometers should be evaluated for their compatibility with the fluid under assessment. Equipment manufacturers can provide procedures for apparent viscosity measurement and calculation.

Summary

Overall, viscous injectable formulations often have high concentrations of large molecules or non-aqueous solvents. With large protein biologics popularizing the drug therapy market, viscosity calculations for viscous products are essential for determining delivery mechanisms and accurately filling parenteral products. A Newtonian fluid is a fluid where the stresses from fluid flow are linearly correlated to the strain rate. This article details calculations for the apparent viscosity of non-Newtonian fluids. Most fluids of low molecular weight are Newtonian fluids. In contrast, high molecular weight fluids (such as suspensions and emulsions) are generally non-Newtonian. All in all, when filling a thick parenteral or cosmetic product, ensure you choose a contract manufacturing organization to support your sterile filling needs.

MycoScience is a contract manufacturing organization specializing in sterile syringe and vial filling. MycoScience also offers Preservative Efficacy Testing, Sterilization Validations, Bioburden Testing, Cleaning Validations, Microbial Aerosol Challenge Testing, Accelerated Aging, Microbiology Testing, Cytotoxicity Testing, Bacterial Endotoxin Testing, EO Residual Testing, Package Integrity Testing & Environmental Monitoring services medical devices and allied industries. MycoScience is an ISO 13485 certified facility.

References

United States Pharmacopeial Convention. <1911> Rheometry. Rockville, MD, USA. 2021. (USPC <1911>).

Sharing this in your social netwroks